Choosing the right materials for environments exposed to extreme temperatures and harsh chemicals is critical for safety and longevity. Many industries, including petrochemical plants, power generation, and manufacturing, require solutions that withstand these rigorous conditions. For those searching online for Refractory Materials in Houston, TX it’s important to understand which products offer both high heat tolerance and chemical resistance to ensure optimal performance and reliability.

Understanding Refractory Materials

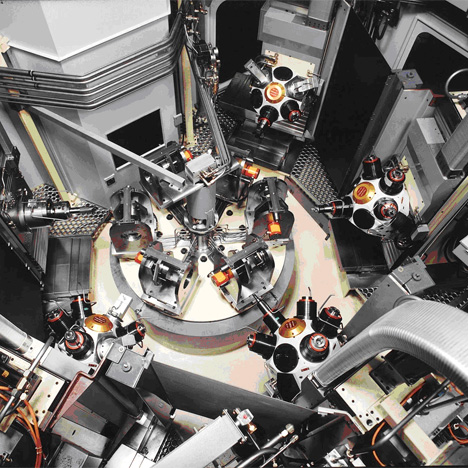

Refractory materials are specifically engineered to retain their strength and integrity under high heat and corrosive environments. They are essential components in furnaces, kilns, incinerators, and reactors, where ordinary construction materials would quickly fail. These products are formulated using ceramics, minerals, and chemical binders, each selected for its unique properties.

Key Considerations When Selecting Refractory Materials

Finding the right refractory product involves evaluating several important factors:

- Temperature Rating: Ensure the material’s maximum temperature rating exceeds the highest process temperatures expected.

- Chemical Compatibility: Match the material to the specific chemicals and atmospheres it will encounter.

- Thermal Shock Resistance: Select materials that can handle rapid temperature changes without cracking.

- Mechanical Strength: Consider the load-bearing requirements of the application.

- Installation Method: Choose between shapes (bricks, tiles) and monolithic (castable, gunnable) materials based on project needs.

Types of Refractory Materials Available

Several types of refractory materials are commonly used in high-demand applications:

- Fireclay Bricks: Cost-effective and suitable for moderate temperatures.

- High-Alumina Bricks: Offer superior heat and corrosion resistance.

- Silica Bricks: Ideal for high-temperature applications, especially in steel manufacturing.

- Castables and Mortars: Provide flexibility for complex shapes and repairs.

- Insulating Refractories: Minimise heat loss and improve energy efficiency.

Ensuring Long-Term Performance

Proper installation and regular maintenance are as important as selecting the right material. Working with experienced professionals ensures that refractory linings perform as intended, reducing downtime and extending equipment life.

For those in need of expert advice and reliable products, Applied Refractory stands out as a trusted partner for sourcing and installing high-quality refractory materials in Houston, TX, ensuring both safety and operational efficiency.