Valves can either be externally controlled, or they can be designed to offer self-control of the flow of the media through the system. Externally controlled valves are controlled with a solenoid, or they may be designed with manual control.

The inline check valve is not externally controlled, so it is often considered a simple component in any system. However, these valves serve a critical purpose in all types of applications from vacuum systems used in dental offices to ensure that air compressors function correctly.

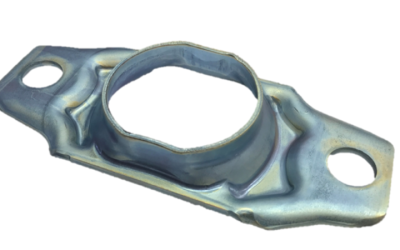

The inline check valve, as the name implies, is fitted into the line. The inlet and outlet port and the valve body are streamlined, and there is no external handle or knob on the valve. These valves can be plastic or metal, and the specifics of the application make one or more materials the ideal option for the valve.

Pressure Considerations

The design of the specific inline check valve includes operation within a pressure range. The pressure on the inlet side of the valve allows the air, or the gas or liquid, to flow through the valve as long as the pressure is maintained above a pre-set level.

Should the inlet pressure drop below this level, the valve immediately shuts, preventing any backflow with the pressure drop. The valve does not open until the inlet side builds up enough pressure to push the ball or the valve closing component out of the valve seat.

Additional Considerations

Other factors to consider with these types of valves include the temperature of the media, the type of environment where the valve is used, and the risk of damage, impact, or vibration on the valve.

In most types of applications in vacuums and compressors, as well as in pneumatic lines and systems, plastic valves are an ideal choice for durability, weight, and resistance to damage and corrosion.